| UA | RU | EN | |

|

PRODUCTS |

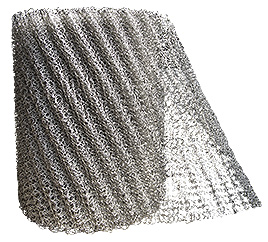

Knitted wire meshOne of the main types of manufactured products of the company's plant is a sleeve knitted mesh (SRP, SRG, SRGM) knitted from stainless wire AISI 321, 316 Ti, in accordance with the developed by us TU U 28.7-30895845.001-2001 and approved by the State Standard of Ukraine, the Center for Standardization metrology and certification. Our products are successfully used at the leading enterprises of the oil and gas and chemical industries.

The mesh is a component for mesh fenders in technological devices, flame arresters, filters, and is used as a packing. The mesh designed for separating the entrained liquid from the steam (gas) flow in distillation, adsorption, stripping and other column apparatus, as well as separators, scrubbers, dust collectors, filters, dryers and many other devices.

In addition to SRP, our company produces SRG corrugated mesh, profiled on chevron rollers to provide even greater elasticity and bulk (as shown in the figure on the left). Corrugation height - 9 (+/-1) mm., distance between corrugations 17 (+/-2) mm.

The updated design made it possible to evenly distribute the working flow throughout the entire volume of the packing, which significantly improved the characteristics of the technological apparatus as a whole.

Mesh fenders manufactured according to OST 26-02-2016 using a conventional sleeve mesh (SRP, SRG 95 +/- 5 mm wide.) entailed a lot of costs, both material and production. It was not always possible to achieve high quality indicators, and the degree of separation, after some time of operation, fluctuated in the range of 93-96%. Due to the non-uniform laying of the mesh in volume, local blockage of the fender soon occurred, as a result of which the pressure drop in these zones increased excessively, and, as a result, flow breakthrough and premature shutdown of the technological process for repairs. Mesh fenders made using SRGM mesh, thanks to a constructively new type and laying method, do not have the disadvantages present in drop eliminators with SRP and SRG mesh, and the operating time (depending on the environment) has increased by 1.4 - 1.8 times.

The main advantages of using a mesh are that it can be used where the filter material must be extremely stable after exposure to aggressive loads. Confident corrosion resistance, mechanical and thermal shock, elasticity, resistance to high vibration and high temperatures, resistance to destructive gases, dirty, oily and other extreme conditions - this is not a complete list of the advantages of woven mesh. Various use of grids allows to make filters as flat and volumetric, as well as mesh fenders with a wide range of selection of the degree of separation and filtration.

|

||